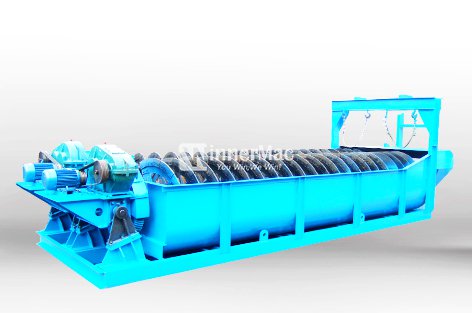

Sand washing and recycling machine

Sand washing and recycling machine

Sand washing & recycling machine is designed based on sand washer and sand recycling system and adopted foreign advanced technology. The machine has ball mill simple structure and multiple function, and is widely used for crushed sand, river sand, lake sand or sea sand washing, screening, recycling and dewatering.

Composite structure of sand washing and recycling machine include: wheel sand washer, high frequency dewatering screen, high pressure cyclone, cleaning tank, return box, high pressure wearable slurry pump, motors, etc.

Step1: washing--

The electric motor runs slowly with the impeller after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolling with the impeller, and grinding with each other. The impurity covering the sand is washing away. Adding more water at the same time, the strong water flow will take away waste and some low-weight wastes from washing launder. The above is the whole washing process.The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back into the washing launder. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impeller to finish the washing task.

Step2: dewatering--

Qualified sand is shoveled to the dewatering screen directly. This dewatering screen sieve is made of PU polyurethane material which has characters such as no blocking, high temperature resistance, and excellent corrosion resistance, then wet sand moisture can be highly reduced after dewatering.

Customized compact wheel sand washing machine: LZ30-2-65

Step3: recycling--

Waste sand water is extracted by slurry pump into high pressure sediment separator, fine sand is sprayed onto polyurethane screen also for de-watering, the waste water flows back to return box and then flows out.

1. Higher sand quality, lower moisture content.

2.Recycled fine size 0.16-3mm sand, lower mud content

3.Compact structure and easy installation

4.High productivity and 95% of fine particles in the material can be recycled

5.Solve cleaning problem of sedimentation tank and improve economic performance at the same time.

Related Products:

flotation machin

flotation machin Magnetic Separat

Magnetic Separat Spiral Washer,Sp

Spiral Washer,Sp dewatering cyclo

dewatering cyclo Spiral Classifie

Spiral Classifie shaking table,gr

shaking table,gr Vibrating Screen

Vibrating Screen Mini portable Ja

Mini portable Ja leaching tank

leaching tank

Comments

Post a Comment