leaching tank

leaching tank

Dual impeller high efficiency agitating tank is applicable to carbon process and rubber chemical process. Its upper and lower layer of impellers are of steel plate encapsulated with rubber,which are connected by means of bolts. With the features like good equilibrium,easy replacement and long service life.

Cyanide Leaching Tank— Feature Cylinder is covered with Winnermac abrasion resistant and corrosion resistant rubber. The high linear speed of impeller helps increase the agitation capacity of ore pulp. More spot air-filling system.

1.The machine features a reasonable and compact structure, and high transmission efficienty;

2.Twin impeller is used ,which has bigger diameter,lower turning speed,lower agitation power consumption,and lower wear of the carbon;

3.Air is sent to the bottom via pipes , so that it is evenly spared with less bubles; It gives moderates agitation strength, to keep the slurry density and fitness to be basically uniform is the tank, so as to improve leaching ability of the cyandidation and the adsorption intensity.

4.The aeration system and the trasmission system are innovated for the new model of the twin impeller high-effciency leaching agitation tank.

1.The machine features a reasonable and compact structure, and high transmission efficienty;

2.Twin impeller is used ,which has bigger diameter,lower turning speed,lower agitation power consumption,and lower wear of the carbon;

3.Air is sent to the bottom via pipes , so that it is evenly spared with less bubles; It gives moderates agitation strength, to keep the slurry density and fitness to be basically uniform is the tank, so as to improve leaching ability of the cyandidation and the adsorption intensity.

4.The aeration system and the trasmission system are innovated for the new model of the twin impeller high-effciency leaching agitation tank.

Related Products:

flotation machin

flotation machin Magnetic Separat

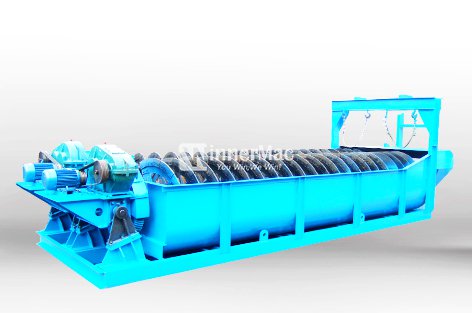

Magnetic Separat Spiral Washer,Sp

Spiral Washer,Sp dewatering cyclo

dewatering cyclo Spiral Classifie

Spiral Classifie Sand washing and

Sand washing and shaking table,gr

shaking table,gr Vibrating Screen

Vibrating Screen Mini portable Ja

Mini portable Ja

Comments

Post a Comment